PRODUCTION PROCESS

OUR PROCESS

PRODUCTION PROCESS

ソファが出来上がるまでの工程を紹介します。ソファは多種多様な素材を使用するため、製造工程も複雑です。より良い製品にするために、工夫を凝らしながら制作しています。

-

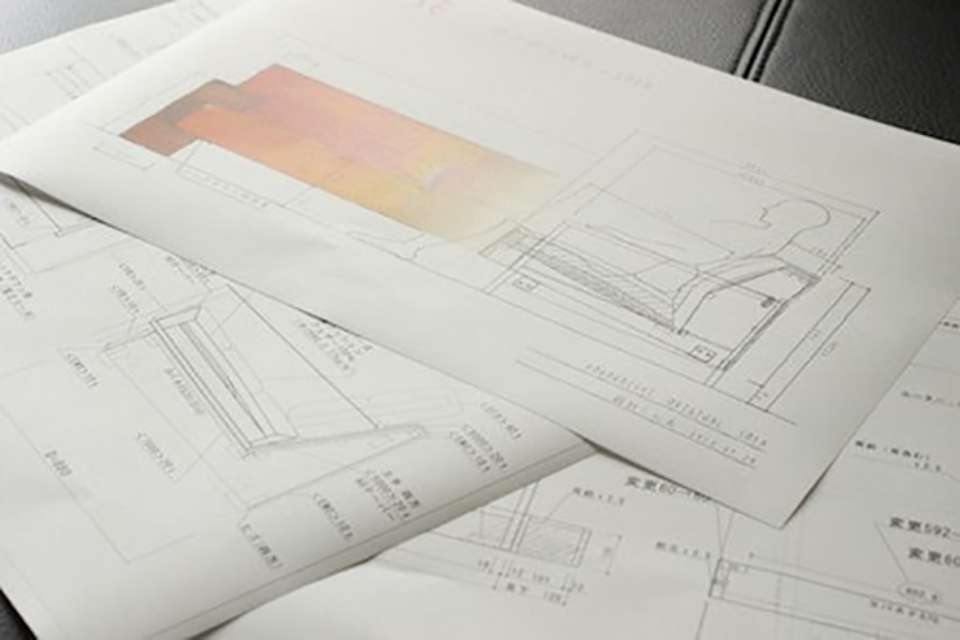

01製作図

We start with examining our designs' intended audience, material strength, texture etc. and transforming them into product specifications and diagrams.

-

02WOODEN FRAMES

The weight and spring supporting parts of our sofa frames are made of solid wood. The other parts are made instead with plywood. This gives our sofas the sturdiness they have for long-term use.

We assemble the frame after processing the wood - ie. carving, shaving and removing corners. Our attention to detail in this process is what gives our sofas their fine finish. -

03下張り(バネ)

Sバネ、ポケットコイル、ウェービングテープ等のバネを使い分け、木枠に張って行きます。バネはソファの座り心地を出す基となりますので、どのバネを使うかは、ソファの座り心地に大きな影響を与えます。

-

04下張り(ウレタン)

The next step is placing the urethane foam on top of the springs. This layer is not visible but is extremely important as it decides not only the shape of the sofa, but also how hard or soft it is.

-

05裁断(布)

We then cut the fabrics to the shapes and sizes as indicated in our specifications. Each fabric type has a different elasticity and we pay attention to this as we shape each piece of cloth.

-

06裁断(革)

Each piece of leather is hand-cut. Our craftsmen take care to form the necessary shapes while avoiding unnecessary flaws of the original cow leather.

Each of our craftsmen is well equipped to both judge and cut the best parts of the hide to use. -

07Sewing

The process of joining the cloth and leather together to create the exterior of the sofa. As we sew the two together, we add in small details such as stitches that add depth to the overall finish of the product.

It takes skill to sew flexible materials straight. We have the experience to handle this and the other work that goes into the complexity in the exteriors of our sofas. -

08Exterior

Placing the exterior on the prepared frame.

The materials used in the exterior can differ in terms of elasticity and how rigid they are, even between individual pieces. Our craftsmen are aware of these variations and work around them to make a consistent finish.

This step involves hammering materials to shape them, sewing the corners etc. - all the hands of our experienced craftsmen with their painstaking attention in making the perfect sofa for you.