CRAFTSMEN

CRAFTSMEN

KOKOROISHI's Craftsmen

The people behind the magic of KOKOROISHI sofas, Each sofa is the fruit of their expertise and collaboration with each other. They make full use of the experience they gain each day and work hard in order to fulfill our customers' wants.

Testsuma Mizukawa - Carpentry

Experience: 9 Years

Mainly focuses on the creation of wooden frames. However, his work also includes NC sawing and wood selection. Wooden frames function as the spines of sofas, and each part actually has a name such as a "bouquet", "trunk" or "treeline". This underlines how the frames may look simple but belie a surprising complexity. A complexity that Testuma skillfully and carefully assembles piece by piece.

Yuto Fujiwara - Sofa Interior

Experience: 7 Years

Yuto moulds the urethane to the curves of the sofa's corners, armrests and slighly sloping back - ensuring that our sofas offer maximum comfort. He bends, wraps and adjusts the foam, skillfully avoiding configurations that would impede other production or cause faults. He even takes effort to suggest how to attach the urethane when we develop new sofa models.

Makoto Ōgaki - Sofa Exterior

Experience: 32 Years

Makoto focuses on consistency, using his tools with prcision, working with efficiency and an eye to details. In earlier eras, sofas were already at a high quality but lately, customers have begun to demand more from what they buy. The exterior work serves as the anchors for the finishing touches to a sofa. Makoto therefore checks thoroughly to see if there are any issues with material or work quality in order to provide each customer with a satisfactory piece. He thinks that compared to before, our sofa models nowadays are better in both polish and quality.

Akimitsu Fujii - Top Cushioning

Experience: 7 Years

Akimitsu focuses on the final steps to the sofa creation process - the application of covers. He can complete this now in two and a half hours per sofa (3 hours for leather), compared the 2 and a half days he would take when he first started to complete the covers for the most complex model. His focus is ensuring a polished look for the sofa. The elasticity of a fabric depends on the individual piece, so Akimitsu uses his experienced sense and touch to decide how much he can stretch the material. He does not interact directly with customers, but makes up for this by scolding and encouraging himself, in the pursuit of excellence.

Chunhwa Kang - Leather cutting

Experience: 15 years

Each piece of leather we use is measured and then cut by our crafstmen. The number of natural marks leather has correlates with its quality, and it is the craftsman's discretion to decide what to include. The rear and head of a cow has different wrinkling patterns, but Chunhwa takes care such that they look the same after her work. She feels that the application of proper cuts, working through leather's natural marks, can add to the finish of a sofa.

* Natural marks: marks to the skin formed by cuts, insect bites, wrinkles, blood vessels etc. while the cow was alive.

Rika Yasuda - Cloth cutting

Experience: 8 years

Handles the cutting of fabric. Fabric cutting is actually the first step in sofa creation - delays in this process will lead to delays further down. Rika therefore carefully checks to see whether fabric delivered to the factory has any defects, on the exact date that they are delivered. It has been 8 years since her joining KOKOROISHI, but she has not actually experienced other factories. She would like the chance to be dispatched to other environnments in order to improve her skills.

Jōji Sakai - Patterning

Experience: 4 years

Jōji has first hand experience as to how an error of a few milimeters can lead to defects in a sofa. He therefore is very careful when creating patterns. He does so based on a sofa design, but adjusts plans based on prototyping, cover replacements, while estimating the amount of fabric needed. Cover replacements are complex work - the original covers may not be a good measure due to degradation, shrinking etc. Therefore Jōji has to make adjustments taking into account these actors. His job is not easy, requiring knowledge of almost all other fields such as carpentry, knitting, urethane, cover attachments, but he gains a lot of satisfaction when his work comes to fruition.

Mizue Yamane - Production Management

Experience: 11 years

Manages the production process - including schedulling cover attachments, material inventory and orders. Previously handled sofa exteriors and also helps out when there are gaps.

The key to making a quality sofa is the attention to detail in its production. How the covers are attached to a sofa depends on both the model and the material. The work is difficult because a small mistake can lead to big changes in how a sofa looks, but she feels very satisfied when a sofa she is involved in is produced with a clean silhouette. Cover attachments are usually done by men because they require strength, but she feels pride at how she can hold her own as a woman in this field.

Toshie Nagami - Sewing

CEO Kokoroishi has experience from cutting cloth all the way to sewing and has been known to say openly that "he can tell the skill level of someone just by the sound of their sewing machine". This has surely intimidated many craftsmen.

On the other hand, he also feels that it is his responsibility to ensure that employees can reach craftsman level and will do his best to guide employees. He has given her many thanks for her work, saying that Kokoroishi wouldn't be where it is were not for the employees. She still remembers the warm feelings from when she first entered and received such thanks.

厳しい顔を見せることが多かった心石会長ですが、「従業員を一人前の職人にするのが、自分の務め」が口癖で、人情に厚く面倒見のいい人でした。あなたたちがいてくれたから、と従業員に感謝し労いの言葉をかけてくれることも多かったです。どこかあたたかくて、居心地の良い職場は、今でも懐かしい思い出として残っています。

Noriko Kambara - Admin

Experience: 10 years

Handles orders, deadlines, production scheduling and phone calls. She watches over the state of production to calculate when she needs to order materials and when sofas can be shipped. She feels very gratified when Kokoroishi can meet customer demands - after all, handling them flexibly is KOKOROISHI's specialty. Ever since KOKOROISHI's Jingumae shop opened, she has had more chances to directly hear customer feedback and see cases where customers actually had KOKOROISHI sofas at home. These experiences have all been a huge motivating factor not just for her, but for everyone in the company.

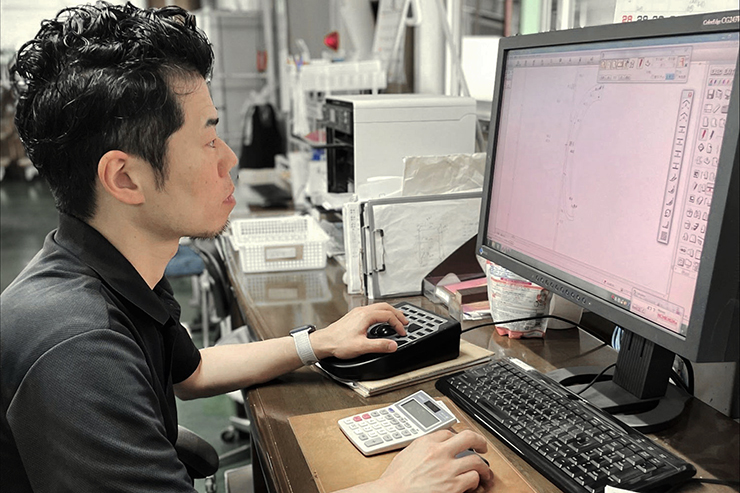

Shinya Iwai - Design

Experience: 2 years

Studied graphic dsign in school, where he got to know about KOKOROISHI and its product design after meeting the designer behind KOKOROISHI's logo.

Had to start from understanding product diagrams when he first joined. When encountering something he wasn't familiar with, he would head down to the factory to compare the diagrams to what was actually being produced. In order to fulfill customers' design requests, he now draws and corrects diagrams as needed, and at the detail needed such that the actual craftsmen on the ground can do their work smoothly.